Online Manufacturer taps into government funding and helps the long-term unemployed return to the primary labor market

Prime example for reintegration of the long-term unemployed: Federal Labor Minister visited Online Manufacturer FACTUREE

Berlin, 21 November 2022 – Someone who has been unemployed for five years or more is considered difficult to place – the Participation Opportunities Act was passed to change this. Federal Labor Minister Hubertus Heil visited the Online Manufacturer FACTUREE (www.facturee.de) and witnessed firsthand how people can be effectively reintegrated into working life after many years of unemployment. The Berlin-based company uses government funding and very successfully employs five people who were previously unemployed for many years. Having gained a foothold in the primary labor market again, they have already assumed important roles in various divisions of the company. Therefore, after the funding ends, they will be offered permanent positions. Hubertus Heil cited this example in his speech to the Bundestag on 10 November 2022: https://bit.ly/3O59hoe

Getting the long-term unemployed back to work was a great challenge for many years. In this context, the Participation Opportunities Act of the Federal Ministry of Labor and Social Affairs, which has been in force since 1 January 2019 (§ 16i SGB II), is intended to improve the employment opportunities of people on the margins of the labor market and facilitate their social participation. The objective of the model is to motivate employers to fill open positions with long-term unemployed persons. Federal Labor Minister Hubertus Heil learned how this works in practice during talks with staff at FACTUREE who are employed via the Participation Opportunities Act.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains: “We are very pleased that we took this step. The instrument gives people whose careers have been derailed a real chance to enter the labor market again. By effectively integrating people who were chronically unemployed, we would like to encourage other companies to follow our example.”

Social labor market offers prospects – initial skepticism vanished

The goal of the Participation Opportunities Act is to support all parties involved. When a long-term unemployed person is hired, the state pays their full wages in the first two years. Then the state pays 90 percent of their wages in the third year, 80 percent in the fourth year, and 70 percent in the fifth year.

Prior to implementation, there were also skeptics at FACTUREE. Moritz König, CEO of FACTUREE, says: “Initially, I had major concerns when I was approached about this issue. I thought that if someone is unemployed for so long, there must be a reason. But I agreed to go ahead because there is practically no risk for the employer. Looking back, I have to say I was actually mistaken … and I’m very happy about that.”

Benjamin Schwab emphasizes: “The model does not guarantee success. Both sides have to be ‘willing’ for the public program to work – employees who are willing to perform, and employers who are willing to be patient and understanding of the very different backgrounds people bring with them.”

The five female and male long-term unemployed persons working at FACTUREE have different career histories. Andreas, storage logistics employee at FACTUREE, was unemployed for a long time and had already given up hope of ever working again. He says: “Thanks to the Participation Opportunities Act, I have now found work in the primary, regular labor market – not in an association or other organization that operates in the secondary labor market. This was important for me. Now my life is structured and I feel optimally integrated.”

Christian, who was unemployed for 15 years, explains: “The Participation Opportunities Act and my employer’s willingness to take a chance restored my quality of life.”

Employers and taxpayers also benefit

All parties benefit from the Participation Opportunities Act – the long-term unemployed, the employers and also taxpayers. Long-term unemployed people get a real opportunity to return to the primary labor market, while companies receive generous wage subsidies that help create new jobs with little to no risk. Taxpayers also benefit because in the long term, fewer people need government assistance.

Rapid growth through public funding instead of venture capital

One distinguishing feature of FACTUREE is that the company has been fully self-financed since it was founded and thus, unlike the usual practice in the sector, operates without investor funds. Five years after it was founded, the company generates 8-figure sales volumes and annual growth rates around 100 percent. Contributing to this positive business development is the fact that from the start, FACTUREE has used public funding programs such as the Participation Opportunities Act that offers pre-financing of jobs.

FACTUREE plans to offer permanent employment

Benjamin Schwab says: “The model works so well for us that we want to offer permanent jobs to all those concerned even after the end of the funding period – i.e. when we no longer receive wage subsidies from the government. We also encourage other companies to make use of the instruments of the social labor market so that even more people can return to permanent employment. We would like to thank the Federal Ministry of Labor and Hubertus Heil for giving us this platform to share our success story with the public.”

Characters: 3,803

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer makes significant contribution to climate protection and creates jobs in Nakhon Province by purchasing CO2 certificates

Fewer emissions and abundant clean energy: FACTUREE supports biogas project in Thailand

Berlin, 15 September 2022 – In Thailand, the production of manioc starch in biogas plants causes large quantities of wastewater, releasing methane into the atmosphere. The Nakhon biogas project from South Pole, developer of international climate protection projects, reduces the emissions and allows for sustainable generation of electricity from wastewater biogas. Online Manufacturer FACTUREE (www.facturee.de) supports this environmental project and assumes ecological responsibility by buying CO2 certificates. The company thus makes a significant contribution to reducing emissions, treating water, creating jobs and supporting educational activities in Nakhon Province.

Biogas is an important addition to wind and sunlight as renewable energy sources. Formerly, wastewater from biogas plants in Nakhon Province was treated in open lagoons. This process resulted in the constant release of methane and a high level of environmental pollution. A climate project finally made a real difference to the situation.

Emission reduction and generation of clean energy

With the Nakhon biogas project, certified with the recognized Gold Standard (Emission Reduction Project Development Standards (southpole.com)), South Pole has developed and implemented a climate protection strategy involving a closed anaerobic lagoon system installed in Nakhon that captures methane emissions and uses them to generate clean energy.

South Pole develops and implements holistic strategies for reducing emissions. The company’s various projects transform climate protection to long-term business opportunities for companies, governments and organizations throughout the world. In addition to reducing emissions, South Pole projects create social and ecological added value – especially for less privileged societies that are threatened by climate change.

Online Manufacturer FACTUREE, a brand of cwmk GmbH, focusses its activities not only on quality but also on sustainability and climate protection and regularly supports relevant projects – including the Nakhon biogas project.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains: “Biogas plants are an important part of energy transition. But they can also be counterproductive if methane escapes into the atmosphere in an uncontrolled way. The Nakhon biogas project solves this problem, considerably improving the local air and water quality in Thailand. By purchasing CO2 certificates from South Pole, we support these developments.”

Generating large water resources

The Nakhon biogas project prevents the emission of powerful greenhouse gases and significantly reduces the use of fossil fuels. The treated water is used in Nakhon Province to irrigate nearby fields, among other things.

Benjamin Schwab says, “Every year, an average of 850,000 cubic meters of wastewater can be treated in the Nakhon project to become a clean water resource. This also benefits fish farming, boosting the economy in the region. The project thus creates jobs for the local population. Various educational activities and social programs are also supported. The entire endeavor is in line with our understanding of ecological, social and economic responsibility, so we are happy to make our contribution here.”

FACTUREE has voluntarily offset its CO2 emissions by purchasing CO2 certificates since the company came into existence. The Online Manufacturer thus promotes sustainability not only with its progressive business model for modern procurement, but also through values such as consistency, environmental awareness and social commitment.

Characters: 3,803

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing, casting, forging, and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer supplies components for attaching batteries to e-mountain bikes of a global bicycle manufacturer

Components from FACTUREE get into gear with GHOST-Bikes

Berlin, 8 August 2022 – The world has seen a real boom in bicycles since the coronavirus pandemic – and those with gears are booming in particular. However, e-bikes require a complex design with a high level of precision. For an e-bike line of bicycle manufacturer GHOST-Bikes, the Online Manufacturer FACTUREE (www.facturee.de) supplies three key components in serial production. The parts are used to attach and stabilize the battery on the frame of the bicycle. The manufactured components also enable GHOST-Bikes to develop and implement functional technical solutions for prototyping within a very short time.

GHOST-Bikes was founded more than 25 years ago in Waldsassen, Germany, and has become a global company, producing over 150,000 bicycles annually. In addition to gravel and mountain bikes, its portfolio also includes mountain, city and trekking e-bikes.

According to GHOST-Bikes GmbH, the complexity of the products in this field is steadily increasing, in particular due to the boom in the electric bicycle sector. At the same time, demand is increasing. GHOST-Bikes has therefore always looked for optimized manufacturing methods that are more efficient and cost-effective while maintaining very high quality. As a result of this, the company commissioned FACTUREE with the Online Manufacturing of various milled and turned parts, bent sheet metal parts, and individual parts in serial production, for example for their E-RIOT e-mountain bikes. The components are also used to support prototyping.

As an Online Manufacturing company, FACTUREE has access to a large manufacturing network of some 2,000 partners in nearly all areas – including CNC machining, sheet metal processing, 3D printing and surface technology. Around 15,000 machines are constantly available for projects. For GHOST-Bikes, one of the crucial criteria was the fact that FACTUREE can offer many different processes – from turning and milling to sheet metal processing and forging – from a single source and in serial production.

Co-founder and CMO of FACTUREE Benjamin Schwab states, “Some of the components we supply for GHOST-Bikes are bent parts for securely fastening batteries to bicycle frames, for example the battery track that helps prevent rattling while driving and keeps the battery secured to the frame. We also supply a forged part that serves as a connector between the kick stand and the bicycle frame.”

Favorable costs and supply times

Due to its online network, FACTUREE is able to have custom components manufactured with a high level of precision by specialized suppliers and to deliver them quickly. For every request, the most suitable manufacturer is selected and the appropriate manufacturing process recommended. All FACTUREE partner companies are subject to continuous, ISO 9001 certified, data-driven quality management.

GHOST-Bikes chose FACTUREE because the Online Manufacturer ensures very short delivery times and offers all manufacturing techniques thanks to its large network of manufacturers. All components were manufactured quickly and demonstrated a high quality. In addition, the pricing and support were ultimately the deciding factors.

Characters: 3.331

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

3D printing can lead to more flexibility and independence from global supply chains

FACTUREE reviews the role of additive manufacturing in re-regionalization

Berlin, 16 May 2022 – The re-regionalization of supply chains is gaining significance in the procurement crisis and can be supported by additive manufacturing. Due to a high level of automation and a relatively low ratio of labor to production costs, even industrialized, high-wage countries in the EU could manufacture more competitively and become more independent on an international level. This is the view of the Online Manufacturer FACTUREE (www.facturee.de) which has an extensive network of some 2,000 manufacturing partners from nearly all areas – currently the company is expanding its range in 3D metal printing, where it sees great potential for the industry, but also limitations.

Supply issues, long distances and material bottlenecks often lead to production delays. Additive manufacturing can counteract this difficulty, as parts can be manufactured locally on demand. Components made by additive manufacturing can thus help avoid supply bottlenecks. Just-in-time production also leads to savings, for example in storage costs, as parts can be manufactured using 3D printing when and where they are needed, eliminating the need to stockpile spare parts, for instance.

“There are high hopes for additive manufacturing with respect to re-regionalization of manufacturing. However, it is not realistic to think we will quickly become independent. There are still too many economic dependencies. Furthermore, additive manufacturing has many technological restrictions that limit its use in industry. One large obstacle is the confusing number of materials and proprietary manufacturing processes, sometimes posing huge challenges for engineers and creating uncertainty. I see a great need for action regarding harmonization and standardization and I am hoping for the consolidation of the market. Nevertheless, the technology has made impressive progress and will continue to build its position,” explains Benjamin Schwab, co-founder and CMO of FACTUREE.

Online Manufacturing with a technology-agnostic approach

FACTUREE is making additive manufacturing and its advantages available to companies. The Online Manufacturer has access to a large manufacturing network of some 2,000 partners in nearly all areas – including CNC machining, sheet metal processing, 3D printing and surface technology. The area of 3D metal printing is currently being expanded.

“When prospective clients ask us for components that were designed as CNC parts but could be made at a lower cost using 3D printing, we point out this option, which is frequently their first contact with additive manufacturing. This is how we promote acceptance. However, the technology is not a one-size-fits-all solution – the right process always has to be found on a case-by-case basis,” says Benjamin Schwab.

FACTUREE selects the most suitable manufacturer for each requirement and recommends the appropriate manufacturing process. “Especially when specific requirements for mechanical properties, tolerances and surface quality have to be met, additive manufacturing is not an alternative to established manufacturing processes such as CNC machining in the industrial setting. The great advantage of our eco¬system is that we are not tied to one manufacturing method but are free to choose the one that best meets the need,” explains Benjamin Schwab.

Characters: 3,475

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Online Manufacturer with broad manufacturing network keeps prices stable even during raw material crisis

Procurement sector struggles with large fluctuations in prices: FACTUREE maintains its offers valid for 14 days

Berlin, 25 April 2022 – Procurement experts are predicting the end of the era of low-priced raw materials and reliable price calculations. Many manufacturers have drastically reduced the validity of their offers – sometimes to 24 hours or less. FACTUREE (www.facturee.de), however, is retaining its offer validity of 14 days despite the current difficult procurement situation. Here, the company benefits from its extensive network of some 2,000 manufacturing partners that gives FACTUREE more room to maneuver, ensuring stability.

The Russia-Ukraine war and the coronavirus crisis put the international supply chains under further stress in an already difficult procurement situation. Many manufacturers of custom-made parts can no longer offer their customers stable prices for a longer period, giving rise to a significant increase in offers that are valid for less than 24 hours.

Benjamin Schwab, co-founder and CMO of FACTUREE, explains: “The current market situation in procurement is making conditions for industrial buyers extremely difficult. The ever-shorter validity of offers that we are increasingly seeing with conventional contract manufacturers and material dealers makes planning nearly impossible for buyers. What was valid yesterday may be obsolete today. However, we do not pass price increases on to our customers and continue to maintain our usual offer validity of 14 days.”

FACTUREE is able to ensure this stability because the company has access to a manufacturing network of some 2,000 partners – mainly from the areas of CNC machining, sheet metal processing, 3D printing and surface technology. As a result, FACTUREE is in a better position to compensate the impacts of market developments through the careful selection of manufacturers. “We are also in a good position to negotiate with partners because as a platform, we bundle customer inquiries, thus achieving a greater order volume than an individual customer, resulting in a positive effect on offer prices. Furthermore, we frequently absorb price increases ourselves at the cost of our margin in order to give our customers more planning stability,” states Benjamin Schwab.

The future of procurement is in platforms

For every project, FACTUREE uses AI to select the most suitable manufacturer in terms of quality, price and delivery times. All manufacturing partners are subject to a continuous data-driven, ISO 9001 certified quality management system. The request process is semi-automatic, thus ensuring faster offers. The logistics partners are also checked for reliability before being selected. Prototyping projects can be implemented as well as small and large series production, which is continuing to grow.

Benjamin Schwab says, “Many industrial buyers are currently turning to alternative procurement methods and sales markets. As we see it, models based on dependence on one provider have become obsolete. Networking is taking hold in the industry, not only in the technical sense, but also with respect to cooperation among different stakeholders. The future belongs to platforms and ecosystems.”

Characters: 3,305

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

In times of crisis, Online Manufacturing ensures more stable procurement processes through a production network

Ukraine war adds to the procurement crisis – Online Manufacturing by FACTUREE offers advantages over contract manufacturing

Berlin, 30 March 2022 – Local industrial companies are watching the Russia-Ukraine conflict with concern. The war has already had a negative impact on international supply chains, prices and procurement processes. As a result, many industrial buyers have had to rethink their strategies. With its Online Manufacturing concept, FACTUREE (www.facturee.de) helps to overcome difficulties in procuring materials. Compared with conventional contract manufacturing, the risk of delays and non-deliveries is much lower because the Online Manufacturer can adapt more quickly to new circumstances, thus minimizing supply bottlenecks.

German industrial companies have been coping with procurement problems for several months. The situation is now intensifying considerably due to the Russian war in Ukraine. The demand for custom-made parts is consistently high, but the sanctions against Russia threaten trade movements. Free capacities and raw material are often in short supply. At the same time, prices are increasing, accelerating inflation.

Change of strategy towards alternative procurement routes

Especially for traditional procurement processes through conventional contract manufacturing, huge disadvantages such as supplier dependencies and interruptions in supply routes have now emerged. In many manufacturing companies, this has led to a change in strategy – diverting to alternative procurement and sales markets. Companies are also looking closer at substitutes for raw and other materials. Furthermore, more efficient manufacturing processes are being explored. One aim of these efforts is to reduce dependency on Russia, Ukraine and other countries as well.

Benjamin Schwab, co-founder and CMO of FACTUREE, states, “We have developed an alternative to conventional contract manufacturing to achieve independence. Thanks to some 20,000 partners in our manufacturing network, we can tap into a huge pool of capacities for our orders. This allows us to react to new developments considerably more flexibly and reliably than conventional contract manufacturers.”

FACTUREE’s manufacturing partners are in the areas of CNC machining, sheet metal processing, 3D printing, and surface technology. For each project, FACTUREE uses AI to find the most suitable manufacturer with respect to quality, price, and delivery time. The request process is semi-automatic, thus ensuring fast proposals. The logistics partners of the Online Manufacturer are selected based on factors such as reliable delivery.

Benjamin Schwab says, “Because we are always informed of the capacities of our manufacturing partners, we can distribute or reallocate orders according to the respective requirements. This allows us to adjust our activities relatively quickly to new circumstances, such as trade route restrictions. We generally do not pass on increases in material costs to our customers and adjust the prices only when absolutely necessary.”

Characters: 3.157

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Engineering and service provider for the space technology sector turns to Online Manufacturing for procuring prototype components

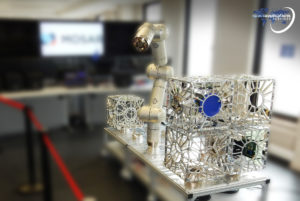

Online Manufacturing goes to space: FACTUREE supplies complex components to Space Applications Services

Berlin, 23 February 2022 – Online Manufacturing by FACTUREE (www.facturee.de) is exploring new spheres as Space Applications Services (www.spaceapplications.com), a specialist in space technology, decided to use the B2B platform for procuring complex components. These include parts for building prototypes and space qualification models used in aerospace applications. The CNC parts are manufactured with the highest level of precision and will be delivered with short turnaround times.

Space Applications Services NV/SA, with headquarters in the Brussels region and a subsidiary, Aerospace Applications North America, in Houston, Texas (USA), specializes in the development of systems and software for the European Space Agency (ESA), national space agencies, and the aerospace industry. The company develops international solutions and technologies for manned and unmanned spacecraft, Earth observation, science, exploration, and communication in this sector.

Special components needed for prototyping in robotics

The aerospace sector is of great importance for Space Applications Services. To ensure the highest quality and reliability in this highly sensitive area, complex components are required for prototyping and what are known as space qualification models.

Dr.-Ing. Torsten Siedel, Project Manager at Space Applications Services NV/SA, explains, “We had to make changes in how we procure these components, as the previous supplier no longer met our requirements in terms of material quality, delivery times, and pricing. We then thoroughly researched providers and decided to collaborate with FACTUREE – The Online Manufacturer.”

FACTUREE is a trademark of cwmk GmbH and has a wide production network with around 2,000 manufacturing partners in the areas of CNC machining, sheet metal processing, 3D printing, and surface technology. More than 15,000 machines are constantly available for projects, ensuring timely deliveries. All partners comply with the requirements of a continuous data-driven, ISO 9001 certified quality management system.

Online Manufacturing of high-quality CNC-machined parts

FACTUREE – The Online Manufacturer supplies high-quality CNC parts to Space Applications Services, enabling the company to use a particularly modern form of procurement. With its online network model, FACTUREE is in a position to provide custom components manufactured by specialized providers with a high level of precision and ensure fast delivery. As the only contract partner involved, FACTUREE is responsible for selecting the most suitable manufacturer and handling the entire process.

The procurement process for components is straightforward – engineers from Space Applications Services create drawings and 3D data that are submitted to FACTUREE. The Online Manufacturer then generates a quote within one to two days. After the order is placed and delivered, all parts undergo a quality inspection at Space Applications Services. Any reworking required is quickly implemented by FACTUREE.

“For more than two years, FACTUREE has supplied us with high-quality CNC parts for various applications and projects. In addition to the high quality, we appreciate the fast delivery times and attractive pricing. The professional, uncomplicated communication also allows us to solve problems quickly, again underscoring the reliability,” says Dr.-Ing. Torsten Siedel, adding “Considering our positive business development that will lead to an increasing demand for CNC parts, we will certainly continue to turn to FACTUREE with corresponding orders in the future.”

Characters: 3,814

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de

Our manufacturing platform represents the modern procurement of production parts. We will convince you of this at the "Supplytech's Digital Conference Pitch" on 17 February. Be inspired by leading startups in the field of procurement from 4pm-5pm. We hope you will conclude "Perfectly Pitched!".

FACTUREE‘s B2B manufacturing platform is predestined for international use

FACTUREE expands Online Manufacturing to a growing number of countries – greater focus on Italy

Berlin, 24 January 2022 – The Online Manufacturer FACTUREE with headquarters in Berlin is expanding its international activities at the start of the new year. The company, which already generates a third of its revenue in other European countries, is now tapping into the Italian market as well. Customer support in Italian is available starting immediately and in parallel with this, the Italian website (www.facturee.de/it) was launched. As a specialist in the procurement of custom engineered parts, FACTUREE sees great potential for new projects in the currently growing industry in Italy.

Italy is one of the most important industrial countries in Europe. Its machine and plant sector is a driving force for the economy of the whole country, with a large proportion of exports. There is a growing trend towards using Industry 4.0 technologies in Italian manufacturing companies. In the 2nd and 3rd quarters of 2021, the gross domestic product (GDP) rose considerably more than anticipated with 2.7 and 2.6 percent over the respective previous quarter in real terms. In the period from January to September 2021, produc¬tion in the manufacturing industry grew by 16.5 percent compared with the previous year and by another 1.4 percent in the 3rd quarter of 2021 over the already good 2nd quarter.

Germany and Italy, the countries with the largest industrial production in Europe, work together in many areas. In a close cooperation in Industry 4.0, the Italian Ministry of Economy – with its comprehensive action plan “Transizione 4.0” among other things – and the German Ministry for Economic Affairs and Energy utilize synergies to jointly promote the scalability and innovative force of Industry 4.0 solutions.

Online Manufacturing breaks boundaries with advantages such as independence

FACTUREE’s B2B manufacturing platform is predestined for international use and supports industry in acting flexibly and independently of pandemic and procurement crises in Italy as well. FACTUREE has a network of more than 2,000 manufacturing partners from nearly all areas – including CNC machining, sheet metal processing, 3D printing and surface technology – with some 15,000 machines. The company can thus consistently provide free capacities and short delivery times. The services are easy to access – even from another country. Companies in countries with less advanced local manufacturing capacities, for example, can benefit from the easy procurement processes.

Benjamin Schwab, co-founder and CMO at FACTUREE, explains, “Implementing in-ternational projects of all sizes has become part of our daily business. In one large project, for example, we manufactured steel pipes and plates weighing 5 tons for the international research center CERN. The European Organization for Nuclear Research in Geneva is one of the world’s largest and most renowned centers for basic physics research.”

Digital platform models are becoming increasingly popular across Europe because they break through the boundaries of conventional models of contract manufacturing – beyond international borders. As an online manufacturing network, FACTUREE can avoid supply bottlenecks even in difficult times by reallocating and can quickly adapt activities to the circumstances. The Online Manufacturer is able to implement prototyping projects as well as small and large series production ensuring the highest quality standards. All partners are subject to a continuous data-driven, ISO 9001 certified quality management system.

Characters: 3,667

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 1000 manufacturing partners from the fields of CNC machining, sheet metal production, 3D printing and surface technology. More than 15000 machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies like Siemens and Parker Hannifin, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de