News · June 11th 2020

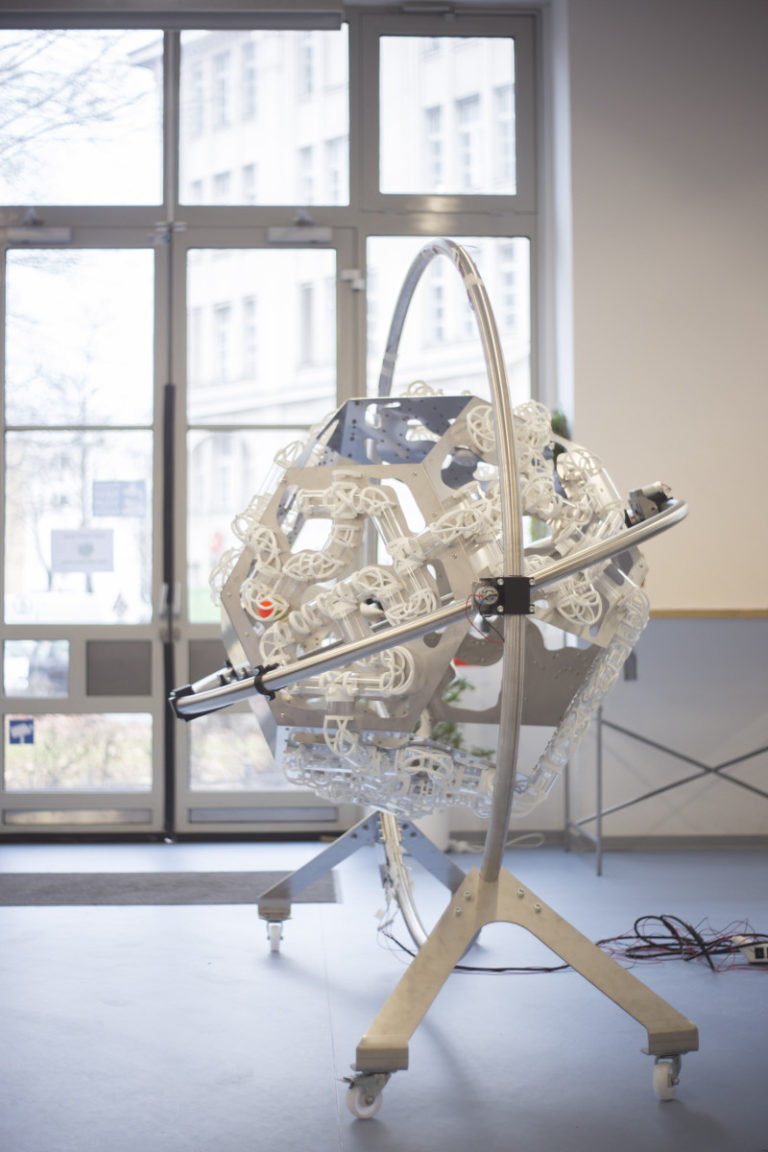

So, what is that object standing in the entrance area of the FACTUREE office? If you approach, you will see a 3D labyrinth with very special content. Numerous hexagons form a structure and the whole thing even moves. What exactly is going on here?

Many may remember it from their childhood days: the ball maze. This was the inspiration for the final assignment of our intern Stephan Winkler. As part of his project, a state-of-the-art interactive construct was created that is much more than a toy: It contains numerous manufactured components. Together with David Recheni, a member of the IT department, the FACTUREE intern designed a machine that incorporates the most common manufacturing processes and materials used by FACTUREE and also adds a playful aspect for the user.

Once the idea was born to create a construction of a mechanically driven three-dimensional labyrinth, the two employees went into the planning and implementation of their vision. After a lot of thinking and practical work, they finally came up with an octahedron stump about two meters high that can be freely controlled and moved by remote control, with a navigable sphere inside the large 3D object. The end result: a state-of-the-art XXL-version of the ball maze.

Keeping the ball rolling: Control via controller and app

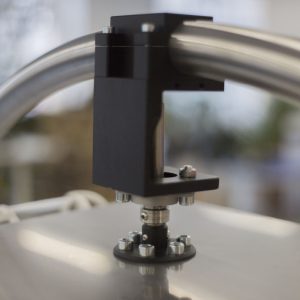

And how does this work exactly? The construction is a volume body that can be moved rotationally on two axes by electrically controlled motors. In this labyrinth, a ball is controlled by rotating the axes on the respective sides of the cube. The goal is to "travel" over as many of the surfaces as possible in a certain amount of time or to reach a predefined point in a certain amount of time.

The modern sculpture is controlled by a controller designed and 3D printed by FACTUREE employees. It contains two joysticks to control the respective axes separately, making it easy to operate the machine. The object can also be controlled via an app on a smartphone.

The sculpture is sure to have a lasting impression on most visitors: in addition to its sophisticated functionalities, the object, which is composed of the FACTUREE logo's hexagons, is also visually well-thought-out. The construction is currently on display as an impressive feature in the entrance area of FACTUREE and will in future be used at trade fairs as to illustrate the extensive FACTUREE manufacturing range of components it consists of: (tube) bent parts made of stainless steel, laser parts, milling parts, 3D-printed parts, turning parts and welded parts including surface treatments.