Case Studies / Press releases · July 23rd 2020

Online Manufacturer supports assembly work at the world’s largest stellarator fusion reactor with CNC-machined special parts

FACTUREE supplies components for fusion research facility at the Max Planck Institute for Plasma Physics

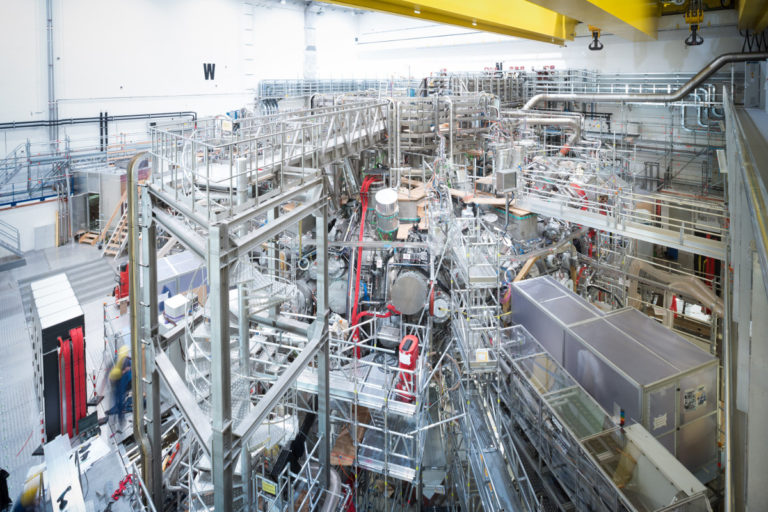

Berlin, 24 July 2020 – The Max Planck Institute for Plasma Physics (IPP), with its locations in Garching and Greifswald, is one of the largest centers for fusion research in Europe. Wendelstein 7-X, located at the IPP sub-institute in Greifswald, is the world's largest and most advanced fusion facility of the "Stellarator" type. It aims to demonstrate the feasibility of this specific facility type for continuous operation as a power plant, making it a key element in international fusion research. For this, the IPP relies on the efficient procurement of high-quality components. The Max Planck Institute, therefore, partners with the online manufacturer FACTUREE (www.facturee.de) to supply components for assembly work at the fusion research facility.

Being one of the largest centers for fusion research in Europe with facilities in Garching and Greifswald, the Max Planck Institute for Plasma Physics (IPP) is a flagship project. With its experimental and theoretical basic research, the institute aims to reproduce the physical processes of the sun on Earth and generate energy from the fusion of atomic nuclei.

In this endeavor, the IPP uses the world’s largest and most modern stellarator fusion reactor, Wendelstein 7-X, which is located in Greifswald and began operating in 2015. As a pioneer in international fusion research, the project’s objective is to investigate the suitability of this special type of facility as a power plant in continuous operation. At the heart of the facility are five superconducting coils that generate a magnetic field cage in which a milligram of hydrogen gas is heated to temperatures greater than 100 million degrees to reach the plasma state.

Higher heat output and plasma discharge require special components

The fusion facility is currently being converted so that even higher heat output and longer plasma discharges can be achieved in the next operating phase. For supplying the assembly tools, support structures, tread plates, special parts for scaffolding, and aluminum and stainless components required for the modification work, IPP relies on “FACTUREE – The Online Manufacturer”.

Broad production network ensures short delivery times

FACTUREE is a brand of cwmk GmbH and has an extensive production network in the fields of CNC machining, sheet metal forming, 3D printing, and finishing technology. The company can draw on a broad range of network partners, production technologies, and finishing treatments that enable fast supply times, a high potential for cost savings, and short-term deliveries on schedule. All FACTUREE partner companies are subject to continuous ISO 9001 certified data-driven quality management.

Andree Benndorf, employee in the Department of Assembly Technology at the Max Planck Institute for Plasma Physics (IPP), says: “We requested several quotes in accordance with the German procurement and contract procedures (VOL). FACTUREE provided their quote very quickly, within one to two days. We were impressed by their broad range of services as well as their pricing structures and short delivery times. FACTUREE has met 100% of its delivery dates up to now. We are also very satisfied with the quality of the components and will push to continue this cooperation.”

Characters: 3,474

Profile of FACTUREE – The Online Manufacturer:

cwmk GmbH, based in Berlin, operates under the brand name FACTUREE as the first Online Manufacturer. The company pursues the goal of enabling its customers to procure modern production parts through digitization, automation and networking. FACTUREE has an extensive production network of over 500 manufacturing partners from the fields of CNC machining and surface technology. More than 6000 CNC machines are constantly available for projects. All partners are subject to a continuous data-driven quality management system certified according to ISO 9001. In addition to CNC turning and milling, FACTUREE's range of services also includes sheet metal processing and 3D printing. FACTUREE can realize prototyping projects as well as small and large series production. The customer base is located in the most diverse fields such as mechanical engineering, medical technology, model making, robotics, automotive as well as aerospace. Leading industrial companies, SMEs, research institutes and universities are among the customers. FACTUREE is active throughout Europe and has a continuously growing number of customers in other European countries.

Further information: www.facturee.de